The manufacturing of armoured vehicles is a highly specialized field requiring not only experienced and uniquely skilled technicians, fabricators and certified welders, but also availability of the latest equipment permanently at disposal to quickly produce the perfect cuts and components for each piece of armoring structure requiring its own unique application. This is achieved by utilizing latest make and models laser machine, water jet, plasma cutter and sophisticated CNC machine while applying numerous types of precision techniques to fabricate the exact and perfect ballistically armored piece per each engineered CAD drawing. Alpine Armoring is proud to lead the field of armoring of vehicles offering its clients the latest in-house available technology unmatched in the industry.

Unlike the competition, Alpine Armoring’s engineering team selectively designs each component for each make and model vehicle applying a variety of ballistic armoured material, including armored plate steel of different Brinell grade (Mil specs 46100, and Mil-A-32332) with Ultra High-Hardness (UHA) wrought steel armor application. The ballistic light steel is typically applied with thickness from 3mm to 14mm offering protection level covering levels of A4 to A12 (including VR7, VR9, VPAM and NIJ Certified levels). In many instances, especially for cars, sedans and SUVs, with many years of field experience in numerous armoring and patents on hand, Alpine Armoring has the luxury to incorporate different composite ballistic material (laminated Dyneema®, woven Kevlar®, many types of polyethylene ballistic and blast protection material), and even various grades of armored ceramic (aluminum carbide, baron carbide and silicon carbide). The uncompromising goal is to retrofit the armoring conversion of the vehicle with the lightest possible method while guaranteeing the most protective structure outcome possible to offer our clients the Perfect Armored Vehicle no matter what the end user’s application is.

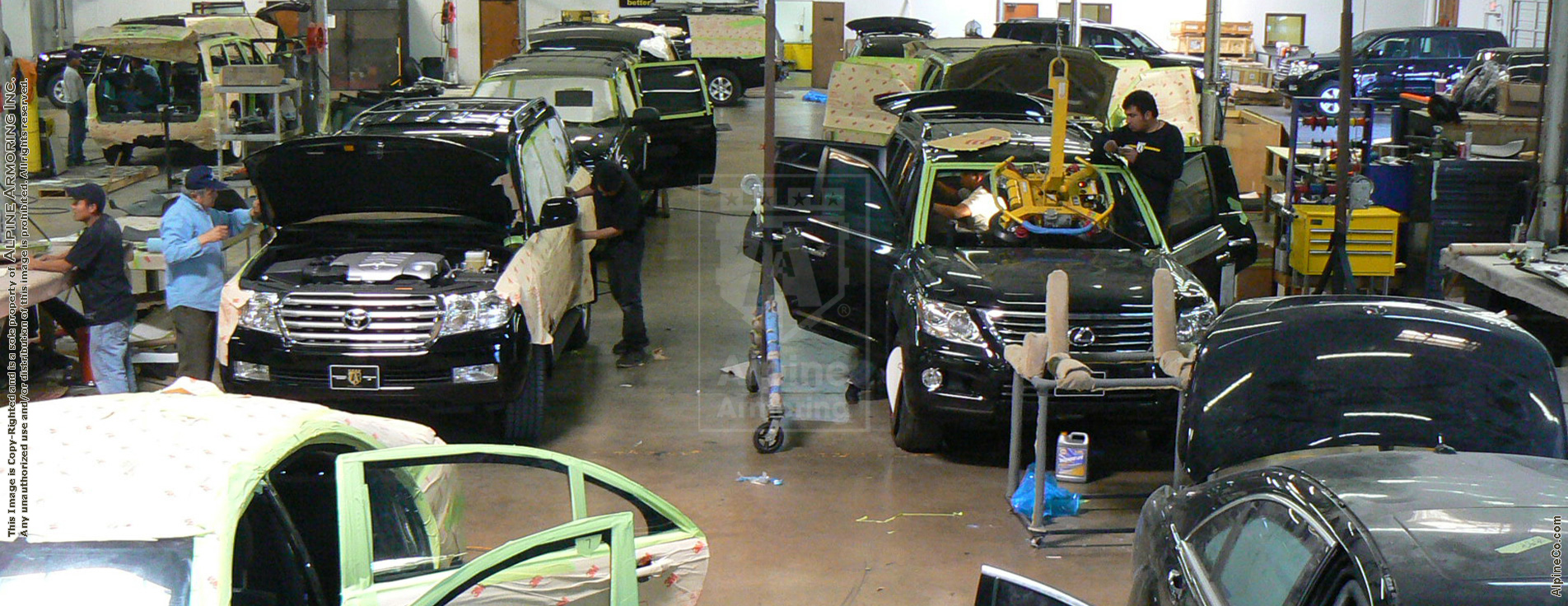

For over the past three decades, with manufacturing plants of well over 150,000 square feet capacity, Alpine Armoring has successfully managed the integration and manufacturing of its armored SUVs, armoured sedans & automobiles and armored trucks (including SWAT and armored APC trucks) to meet the increasing demands of the discerning VIP clients requiring custom-armoring with exclusive specifications. Alpine Armoring is equally positioned to handle mass production of up to 30-vehicles-per-month orders for many of its corporate and institutional clients including fortune 500 companies, the United States Government (nearly all the agencies and departments), the United Nations, various NGOs and over 75 foreign governments. This setup is designed to meet any anticipated larger orders with even faster production timeline to meet each special client’s requirements. Selected orders, as deemed necessary, are exclusively retrofitted at our secured and dedicated area of the plant.