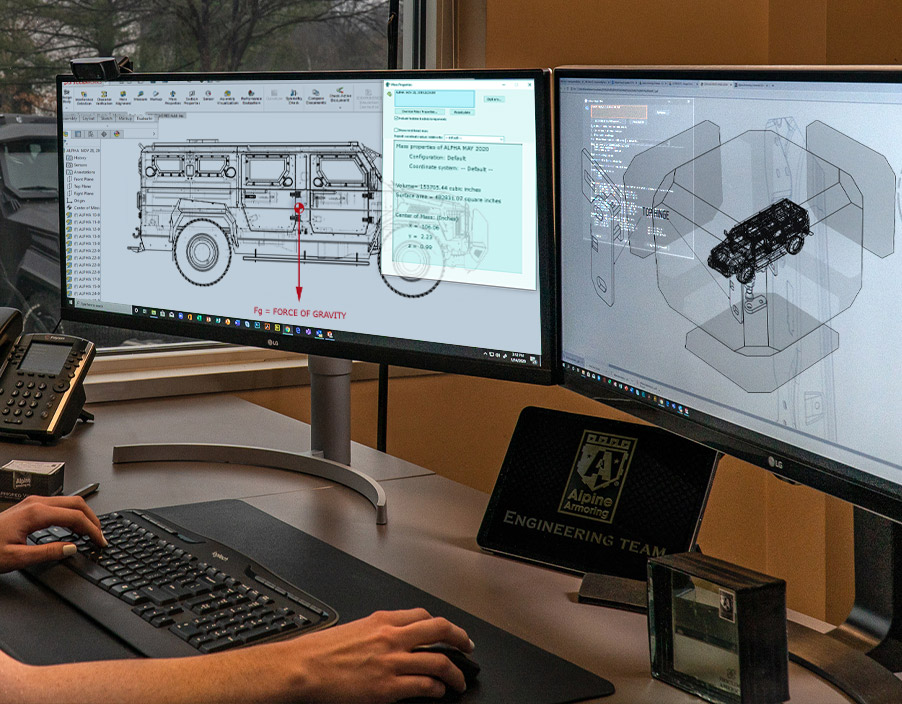

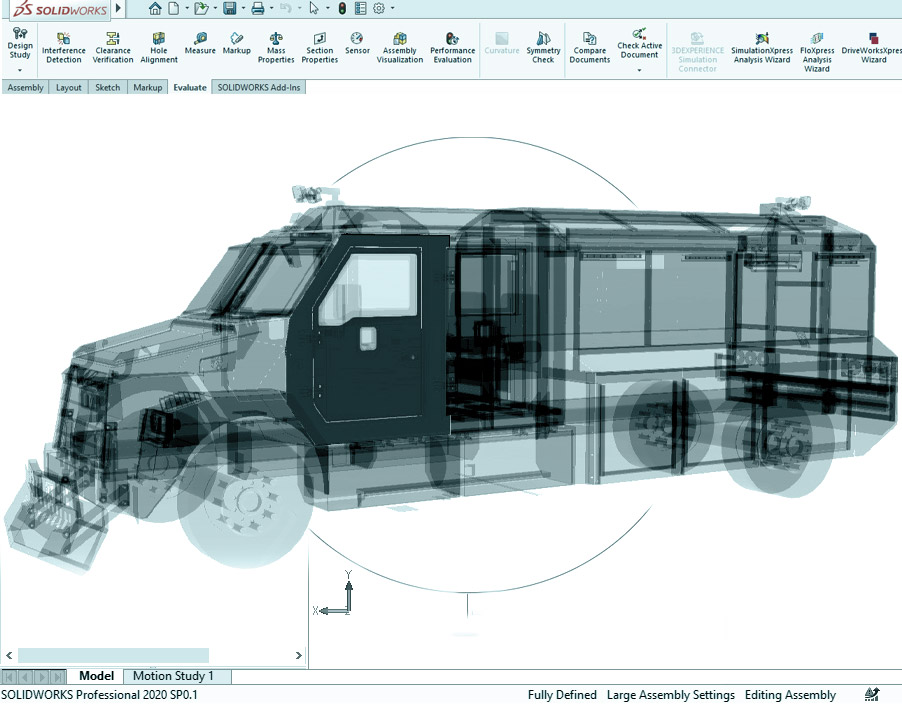

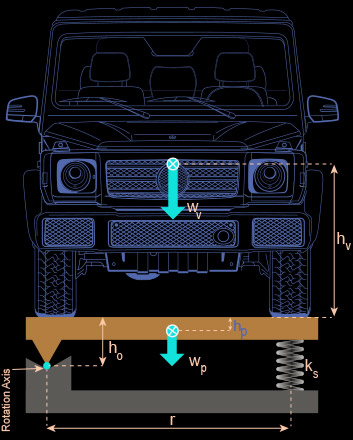

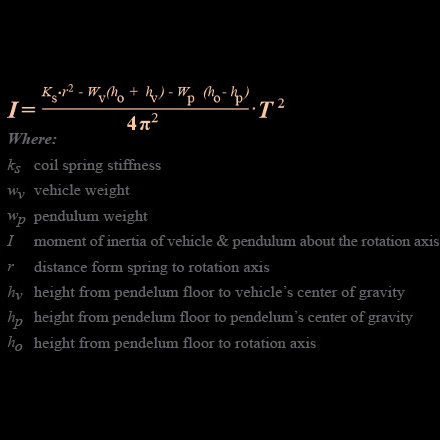

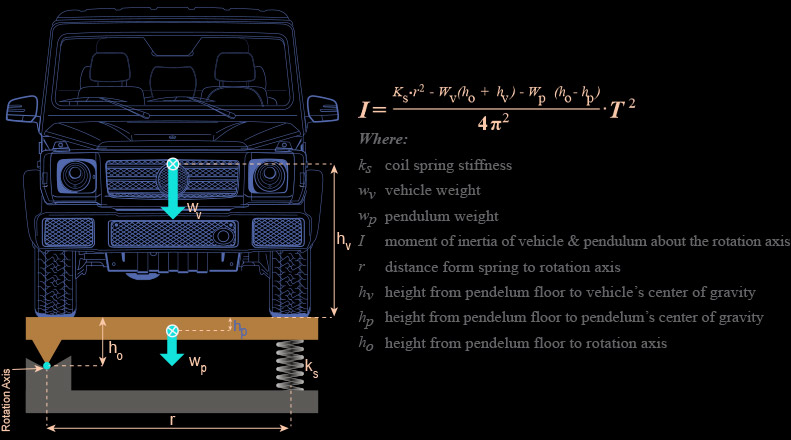

One of the key factors in determining how properly and professionally a vehicle is armored is when the vehicle’s Center of Gravity is correctly measured before and after the conversion. The Engineering team at Alpine Armoring makes certain and adheres to this fundamental point that the stability of an armored vehicle requires optimizing the new point where the final Center of Gravity of the completed vehicle lies and making technical assessment to lower that point when applicable. The goal is to achieve the best performance and handling while offering the most stable armored vehicle for the client whether driven on a paved or off road.

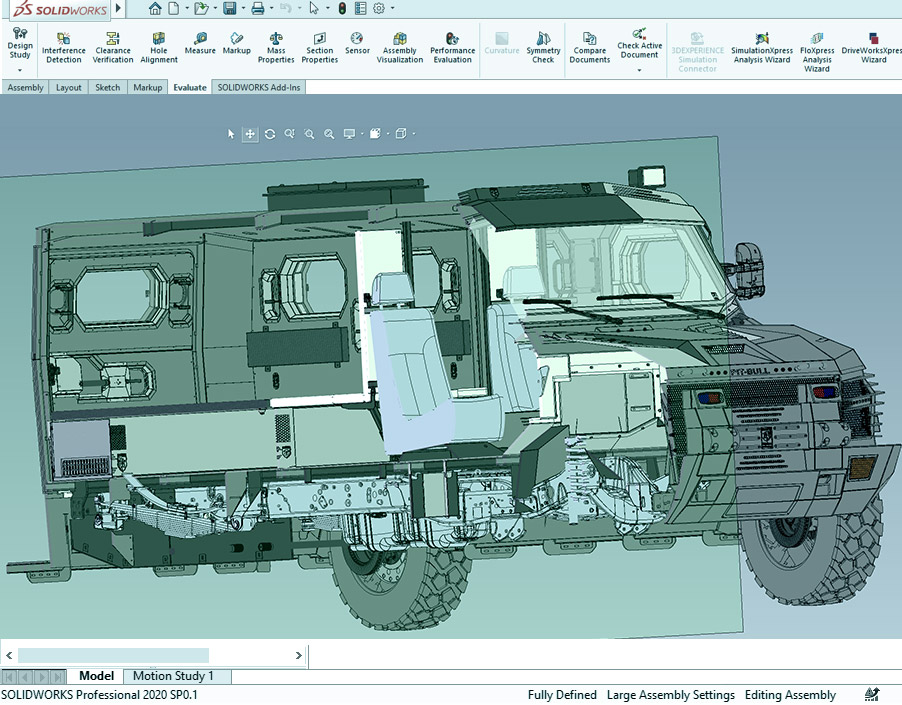

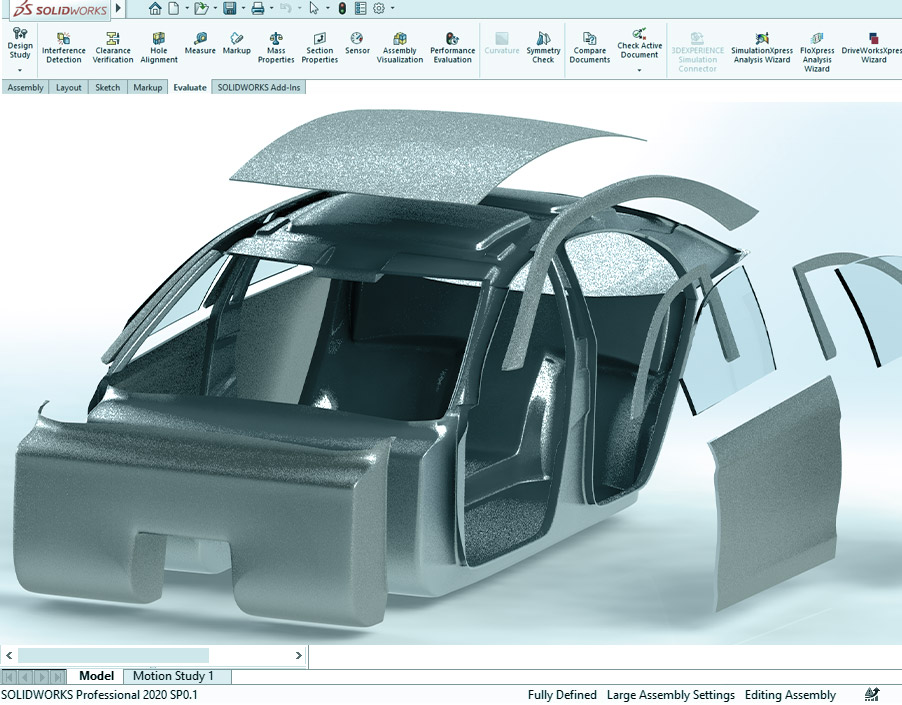

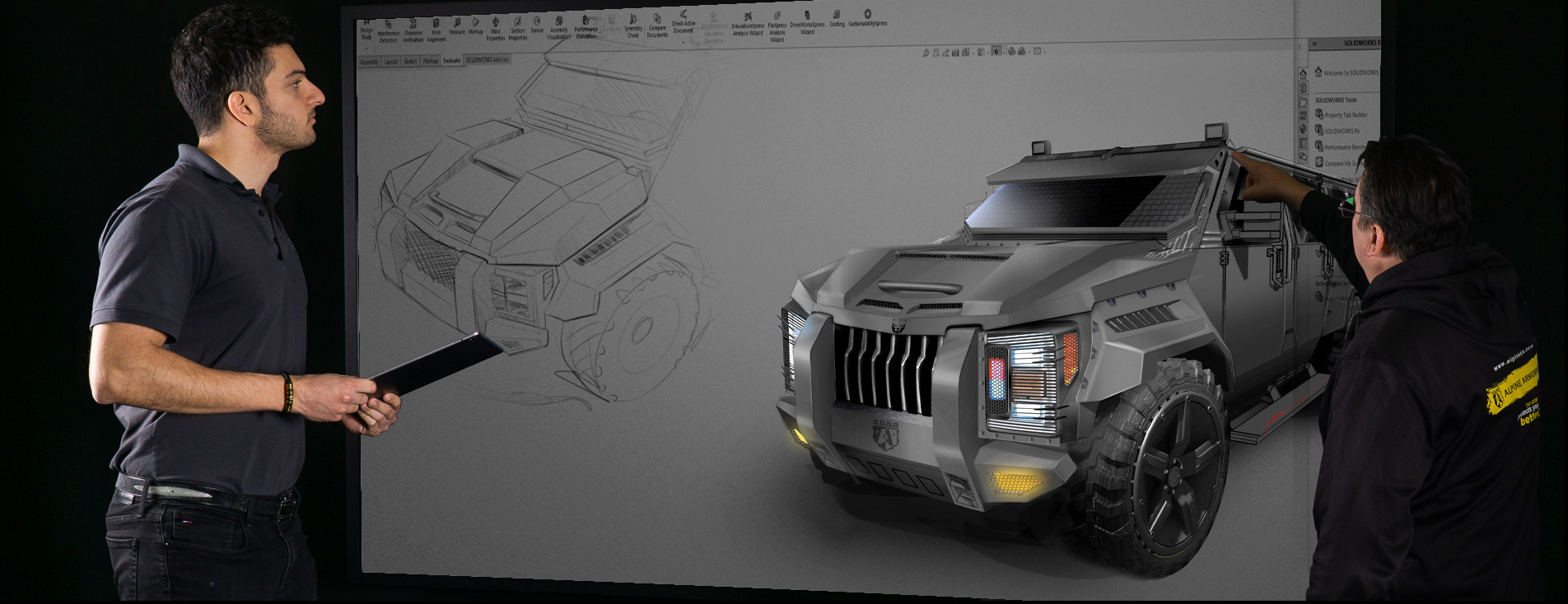

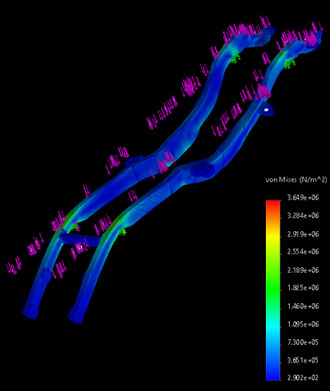

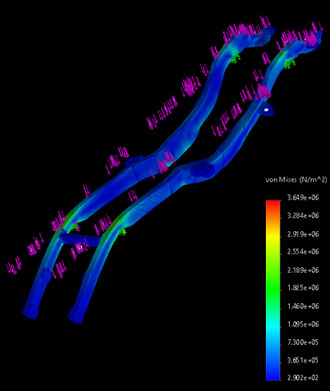

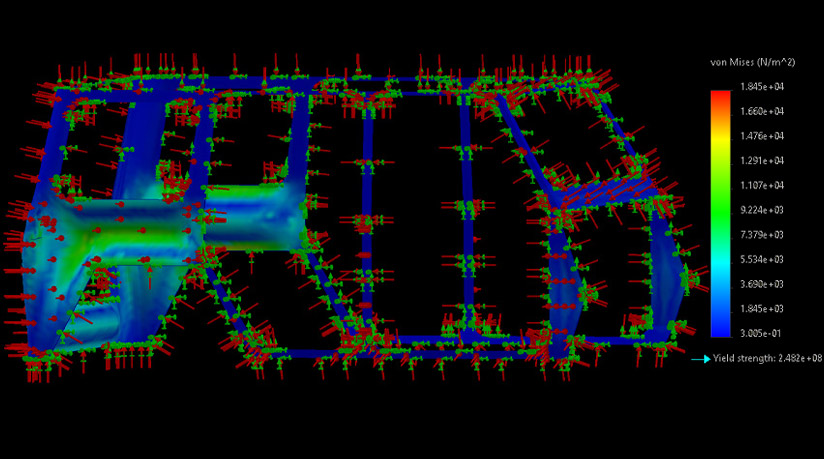

The most important aspect of an armored vehicle is how collectively protective AND safe it is. While that does include resistance to gunfire of different rounds and power, it also includes the driving and handling characteristics of the vehicle with added weight. The Design & Engineering Team at Alpine Armoring sets itself apart from competitors by performing stress analysis on each of the chassis of vehicles during and after completion of the work. This allows for more strategic use of ballistic materials and a chance to improve the handling and rigidity of the whole capsule when the occupants ride in vehicle. That is one more reason why our clients consistently rate Alpine Armoring’s vehicles as the best driving/handling vehicles in the industry.

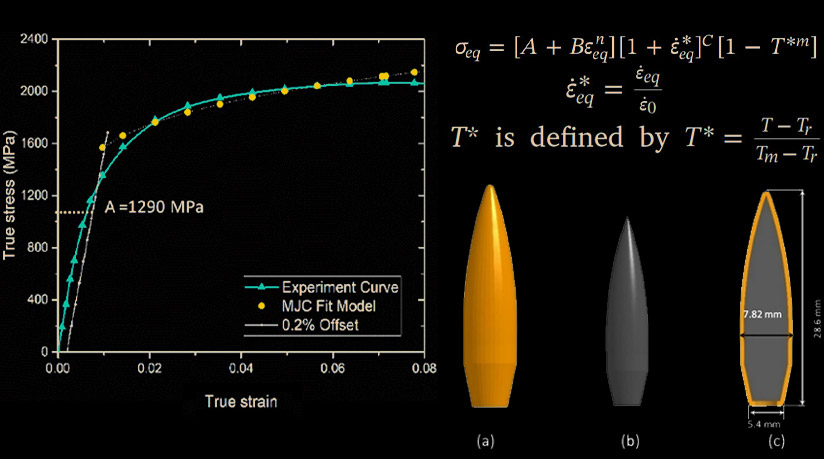

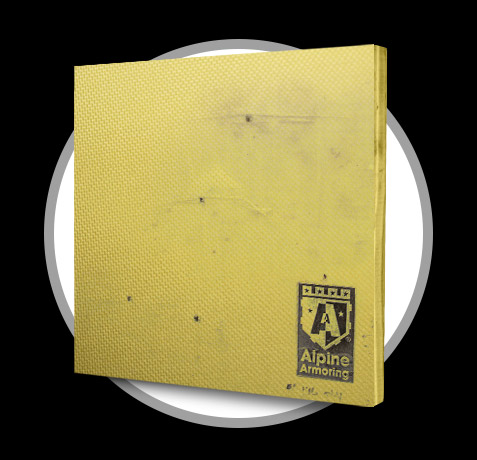

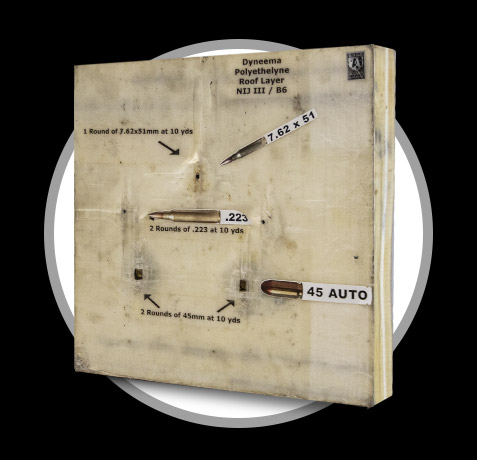

Alpine Armoring prides itself in using a broad range of high-grade certified ballistic opaque materials applied throughout the vehicles. A combination of lightweight Kevlar and Dyneema are often used for selected model SUVs and sedans in addition to ballistic steel. Continuous in-house ballistic testing of the material is also conducted to determine how the material will hold up under extreme line of fire using various high power weapons and different grain/velocity rounds.

A woven type light weight fabric that is “ultra-malleable” that can be shaped perfectly into seams/corners of the vehicle for lower level protection and back-splashed with ballistic steel or ceramic to achieve higher protection.

A specially-laminated Polyethene material is a composite material with light weight characteristics, and it is typically about ¼ the weight of ballistic steel. Aside from its higher price than ballistic steel, it is considerably thicker, thereby making it difficult to reupholster the interior in an OEM fashion on selected model SUVs and sedans. Alpine Armoring applies its unique and patented technique in incorporating this material to many of its armored vehicles to achieve lighter weight and better results at the end.

The most common choice of opaque material used in armoring vehicles. Alpine Armoring frequently uses the special certified lightweight ballistic steel in conjunction with some other composite ballistic material to achieve the lightest armored vehicles in the world. The majority of vehicles armored by Alpine Armoring are at level A9 with the ballistic steel being approximately ¼” or 5/16” thick.

The application Alpine Armoring uses, whenever recommended on certain areas of a vehicle, are Aluminum Carbide, Silicon Carbide and Boron Carbide. All are significantly lighter than steel, yet preferred for certain vehicle armoring applications with varying results.

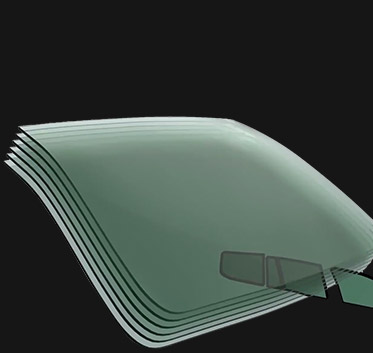

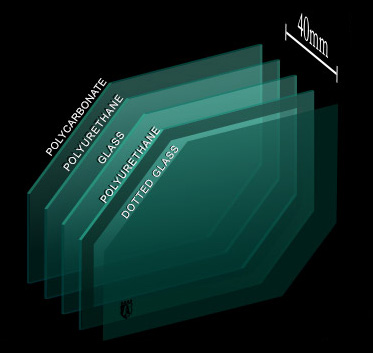

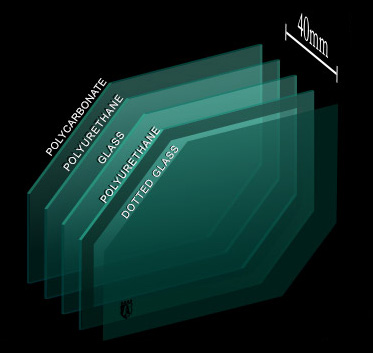

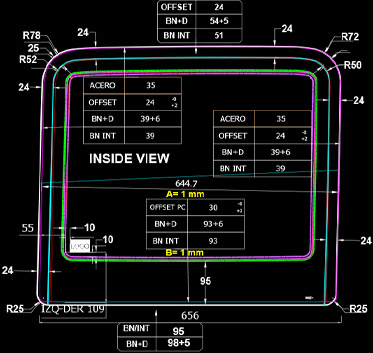

Through decades of experience and exclusive relationships with selected high-quality ballistic glass manufacturers, Alpine Armoring has carefully designed its no spall glass and polycarbonate layers for each make and model vehicles to significantly prevent or minimize delamination from occurring while maximizing optics. Alpine’s material science engineers are currently developing a new polyurethane compound that will decrease the thickness of armored glass.

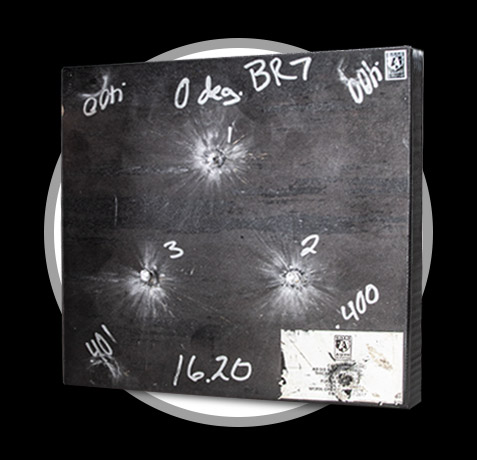

Unlike any other in the industry, Alpine Armoring periodically conducts in-house testing of its ballistic materials and the entire armored vehicles that often exceed the requirements set by the certifying agencies and laboratories. Such tests are also conducted to determine how many rounds a material can actually take using different high power weapons before a penetration occurs, at what angles they occur, and at with what grain/weight of the round. Visit our BALLISTIC VEHICLE TESTING page for more details.

Unlike any other in the industry, Alpine Armoring periodically conducts in-house testing of its ballistic materials and the entire armored vehicles that often exceed the requirements set by the certifying agencies and laboratories. Such tests are also conducted to determine how many rounds a material can actually take using different high power weapons before a penetration occurs, at what angles they occur, and at with what grain/weight of the round. Visit our BALLISTIC VEHICLE TESTING page for more details.